5 min read

8 steps to increase the productivity of your lab

Feb 6, 2024 10:44:13 AM

By:

Jean Peccoud

Feb 6, 2024 10:44:13 AM

We all wish to increase our lab productivity. We have deadlines to meet, publications to write, and patent applications to submit. Since resources are limited and demand always increasing, we are under constant pressure to increase productivity. Laboratory efficiency can be increased by following seven steps that have positively impacted the productivity of teams across many industries.

Assessing Laboratory Productivity

Is your lab consistently meeting its goals and milestones? Can you say your funding is being used to its maximum value? If you answered no to either of these questions, you probably have inefficiencies in your lab that are holding your team back from achieving its full potential.

Think about your day-to-day operations and note how many of the following questions could apply to your lab’s health and performance.

- Does your lab have days frequently filled with problems?

- Do you spend too much time on routine tasks?

- Do you often find yourself generally waiting? This commonly manifests as waiting for steps in a project to be completed, waiting for someone to finish their part of a project, or waiting to use particular equipment.

- Are you often searching for tools, supplies, or information, often to no avail?

- Does your lab have underused equipment?

- Has your lab needed to perform the same experiment multiple times unnecessarily?

- Have you spent time working on low-impact tasks or things that don’t receive a proper follow-up (i.e. collecting data that never gets analyzed)?

- Are your shelves filled with excess perishable inventory that doesn't get utilized properly?

- Alternatively, have you found your lab short on inventory? Has this led to delayed experiments for you, your affiliates, or your customers?

- Are your team members being properly utilized? Do you have Ph.D.-level scientists performing routine experiments?

If you said yes to any of these questions, you could improve your lab efficiency. The good news is that once you have an eye for spotting waste in real-time, it becomes easy to identify and eliminate these issues and prevent future ones. Following these seven steps will get you on a proper path to healthy lab productivity.

8 Steps to Increase Your Lab efficiency

- Eliminate waste. If you said yes to any of the questions above, you have waste in your lab, but take solace in that your lab is not the only one struggling. Waste is defined as anything that does not add value to your work. Common sources of waste in labs include product defects, overproduction, lack of inventory, under-utilized talent, non-approached specialists, training failures, transportation issues, extra processing efforts, and waiting for people, equipment, or reagents.

- Empower your team. We suggest that you train your team to become more productive by becoming waste eliminators. Rather than viewing waste as your team failing, treat it as a group opportunity for improving your lab's health and productivity. You could even gamify the experience to boost team morale and participation.

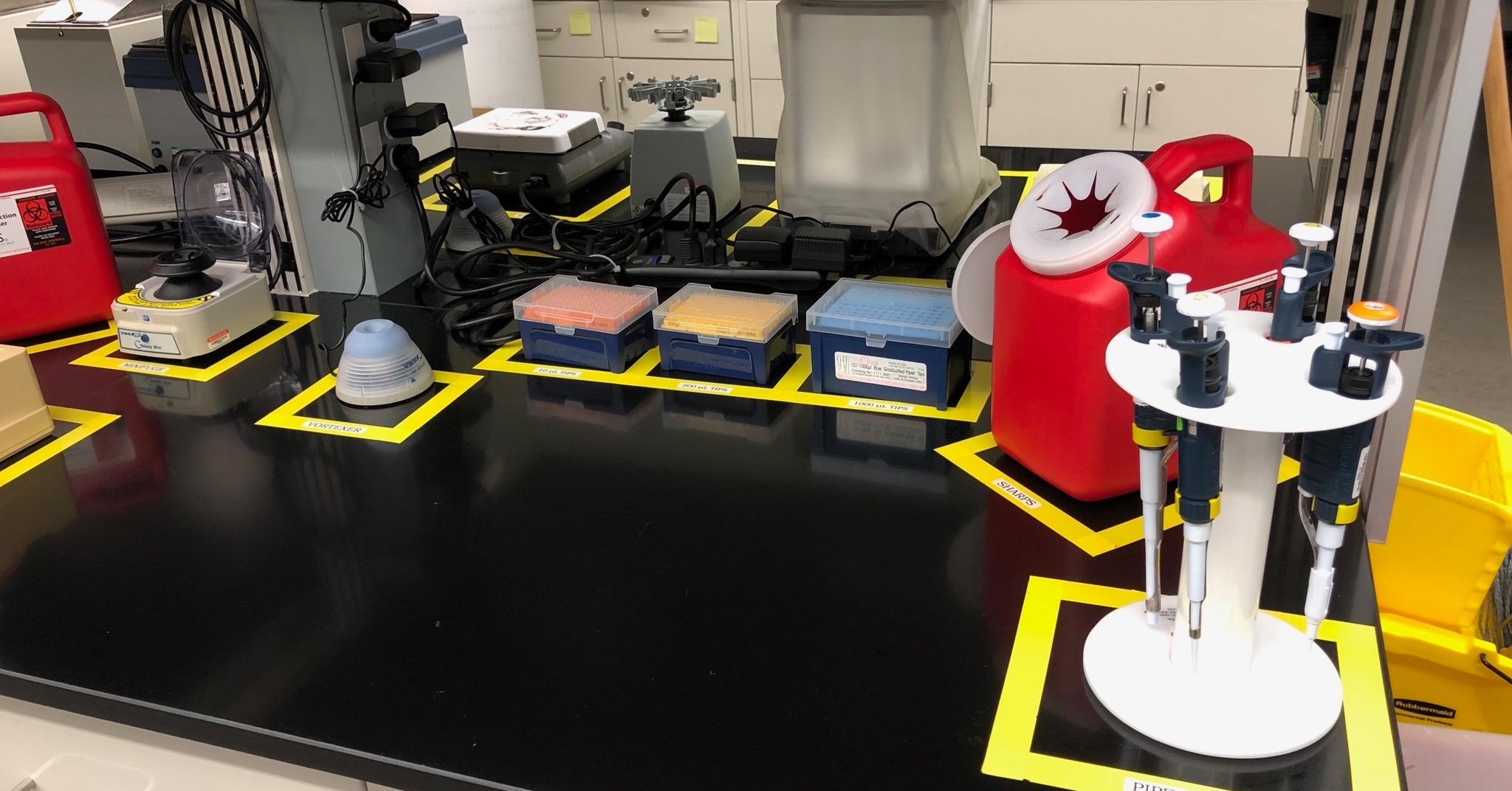

- Organize your lab. Implement a 5S program. 5S is a workplace organization methodology that originated in Japan. By curating a 5S program for your lab, you can greatly reduce or eliminate the amount of time searching for tools, supplies, or information. It is also a powerful tool to improve safety and quality in the work area.

- Track issues. To find and fix lab issues over time, we suggest creating a simple problem tracker solution. This can be easily done by creating a simple spreadsheet. Whenever you have an issue arise, merely write the date and problem description to the document. Over time, you can also track your attempted solutions and this becomes a living quality document for your lab. This is a great tool for easily tracking defects and errors to improve quality over time! After consistently logging your lab problems, your most frequent and possibly elusive challenges will make themselves known. Additionally, we suggest that you empower and challenge your team to come up with new lab productivity solutions. Problem-solving is part of being a research scientist; having the same problem recurrently is an issue that needs to be fixed.

- Manage information. Adopt a Laboratory Information Management System (LIMS). LIMSs provide an environment to track your samples and standardize your protocols. Some LIMS even include Electronic Laboratory Notebooks.

- Label your samples. Mislabeled samples lead to confusion, decreased productivity, and ultimately decreased reproducibility. If your labels are inconsistent amongst all team members, expensive reagents and data are often lost. Use a LIMS system to automate your labeling processes to decrease wasted time, money, and effort. Check out this guide to sample labeling to develop sample labeling best practices that will save time and money.

- Calibrate your instruments. Properly calibrated instruments are essential to ensure the reproducibility of the results produced by your lab.

- Automate your processes. With the ever-increasing need for larger data sets, it is necessary to increase the repeatability and reproducibility of laboratory processes. In other words, without streamlining your resources and research practices your reproducibility falls to the wayside. One of the main benefits of automation is that it increases reproducibility and reduces failure. It is a common mistake to think that automation is limited to physical automation. It is possible to automate laboratory processes without automated instruments.

Use GenoFAB

The GenoFAB App is an information management system that allows your lab to run more efficiently. It allows your team to produce more and better data with its existing resources. More and better data lead to more discoveries, faster product developments cycles, and higher throughputs.

GenoFAB can help!

Schedule a call to to learn how GenoFAB can help you manage your laboratory information and schedule a demonstration.

Recent Posts

What Does a Lab Manager Do And Why Is It Important?

There is a sort of energetic tension in the silence just after a conductor takes the stage. That...

Laboratory Labels: The Ultimate Guide

We all have experienced the frustration of being unable to read the handwritten label on a tube or...

Expression Vector Optimization for Protein Production

Most recombinant proteins can be produced by simply cloning the corresponding genes into standard...